We have been focusing on developing durable finishing agents mainly for polyester fibers for long years.

The production of polyester fibers have been increasing year by year not only for wears but also for industrial uses because of on their strong points of like cost, wrinkle-resistance and UV protection performance compared to natural fibers.

On the other hand, there exist some drawbacks of polyester fibers such as of their handlings and hydrophobic surface which leads to weak absorption of sweat and stain remove performance.

We took this opportunity as a chance and have been developing finishing agents for polyester fibers which covers their drawbacks while keeping their original strong points, and now many domestic and overseas customers use our finishing agents.

Demands for the stain release finishing have been increasing on synthetic fibers and now most of the apparel makers are commercializing the wears through taking specified stain releasing testing method under strict quality control. We also speculate that demands for the quality and safety on the finishing agents will be increasing more and more in the future.

Before introducing our agents, we would like to briefly explain about hydrophilicity and stain releasing.

Most cases for the purpose of hydrophilic finishing on the wears are to improve the wearing comfortableness.

It is said that average human sweat 400 to 600cc per day and it will be more than 10 times when they take an exercise. The hydrophilicity effect is needed when the sweat moves to the fibers from the skin. If the fibers do not absorb the sweat, you will feel the sticking feeling.

To provide hydrophilic effect on hydrophobic fibers is not only obtaining the sweat absorption, it wills also obtaining anti-static effect and the stain releasing effect especially for oily stains.

Major causes of the stains on the fibers are follows.

- Stains which comes from everyday life. Adhesion of both water and oily stains derives from the affinity to the fibers.

- Adhesion of stains derives from static electricity. Stains which carrying the static electricity sticking on the fibers.

- Stain re-deposition at washing process. This will leads to the cause of black stains.

The sticking forces of the stains are dependent on the affinity of the fiber and the stains. Since hydrophobic fibers like Polyester are having strong affinities to the stains especially on oily stains compared to hydrophilic like cellulose, it is hard to remove the stains once they adhered.

it is hard to remove the stains once they adhered.

On the other hand, hydrophilic fibers are easily to absorb especially water stains due to their high surface energy.

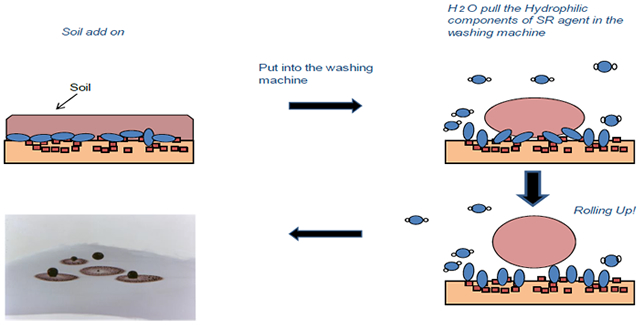

When our hydrophilic agent is processed on the Polyester fibers, they will easily absorb water stains but they can obtain both water and oily stain-releasing effect on the washing process.

This picture shows the wears in the washing machine. As you can see, the oily stains are removed from the Polyester fibers that treated with our hydrophilic agent in the washing tab. This phenomenon is called "Rolling Up phenomenon".

We would like to explain the mechanism of this rolling up phenomenon on the product information page.

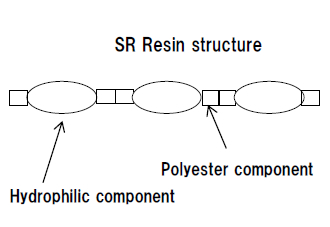

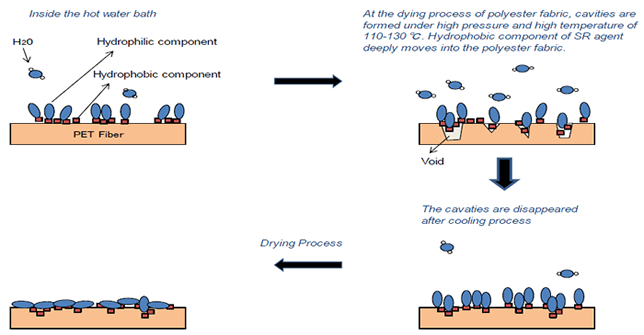

Our SR series are composed mainly from polyester resin that having similar component as polyester fabric and the hydrophilic component. The polyester resin strongly adheres on the base polyester fiber and performs high washing durability.

Expectable Performance

- Provides high washing durability compared to other general surfactants hydrophilic agents.

- Provides hydrophilicity, stain releasing, anti-static, and soft handlings to the polyester fibers. And also, causing hindrance to flame resistance is unlikely with our agents.

- Most of the grades are able to use on both Padding and dyeing process.

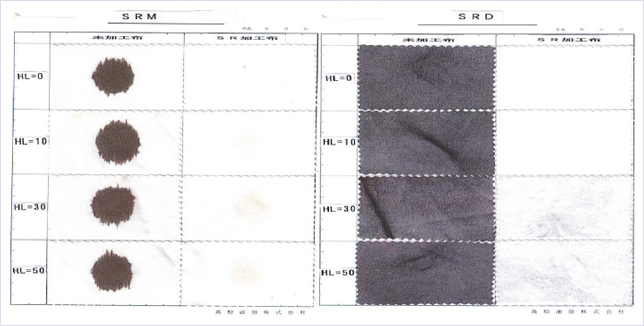

Hydrophilicity data of SR series

There are three types of major methods in order to measure hydrophilicity of the fibers. The one is called "Water dropping test" which measures time until the drop gets lost in the fabric by using 1-ml pipette.

Main cause of the uncomfortable feelings like sticking feeling comes from remaining of the sweat on the body skin. To avoid this, it is important how quickly the sweat moves to the fiber side from the body skin, and "Water dropping test" will be useful for this performance as a reference.

| Washing times | Before | 50 times | 100 times |

| None processed | 180sec. | - | - |

| Competitors’ | 0.2sec. | 0.2sec. | 0.2sec. |

| SR-2010A | 0.1sec. | 0.1sec. | 0.1sec. |

| SR-N7015 | 0.1sec. | 0.1sec. | 0.1sec. |

Testing Condition

Process; Exhaust method Substrate; Polyester 100% Knitting Usage; 3%o.w.f.

Treatment; 130℃×30min.~drying~setting

And to feel more wearing comfortableness, it is also important how quickly the sweat evaporates from the fibers. In order to evaporate the sweat from the fibers quickly, one of the solution is to improving the sweat diffusion properties of the fibers. "Water diffusing method" and "Byreck method" are one of testing method in order to check this performance as a reference.

Testing Condition

Process; Exhaust method Substrate; Polyester 100% Knitting Usage; 3%o.w.f.

Treatment; 130°C×30min.~drying~setting

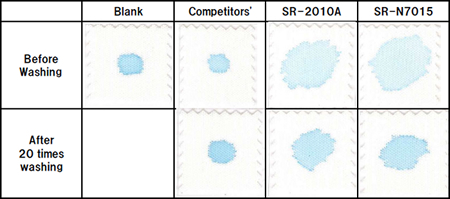

Stain and Soil releasing data of SR series

SRM; Drop a drop of grade B heavy oil with 1-cc pipette on the specimen and leave 24 hours→Launder the specimens and check the oil releasing properties. The left side is none-processed polyester fabric and the right side is the fabric processed by SR-2010A.

SRD; Put the specimens and an artificial staining agent in Launder-Ometer, and launder them→Check the re-soiling degree.

HL-0; Treated fabric without home laundering/HL-10,30,50; Treated fabric with specified times of home laundering

There are two types of major methods in order to judge stain releasing properties. One is called "SRM Method" which confirms soil releasing properties at washing process and the other is called "SRD Method" which confirms re-soiling properties at washing process.

As you can see from the data, our SR agent shows excellent durable-stain releasing property compared to none processed fabric.

Last, we would like to show why our SR agents provide excellent hydrophilicity and stain releasing property with high washing durability for Polyester fabrics.

SR Agent adsorption Mechanism

Stain & Soli release Mechanism

TAKAMATSU OIL&FAT

![Contact us[Mon〜Fri]9:00AM〜6:00PM +81-6-6262-3288](/english/images/common/head_tel.jpg)